ALtracs® Plus – high strength thread-forming into cast metals

How ALtracs® Plus delivers time and cost-saving potential over metric screws

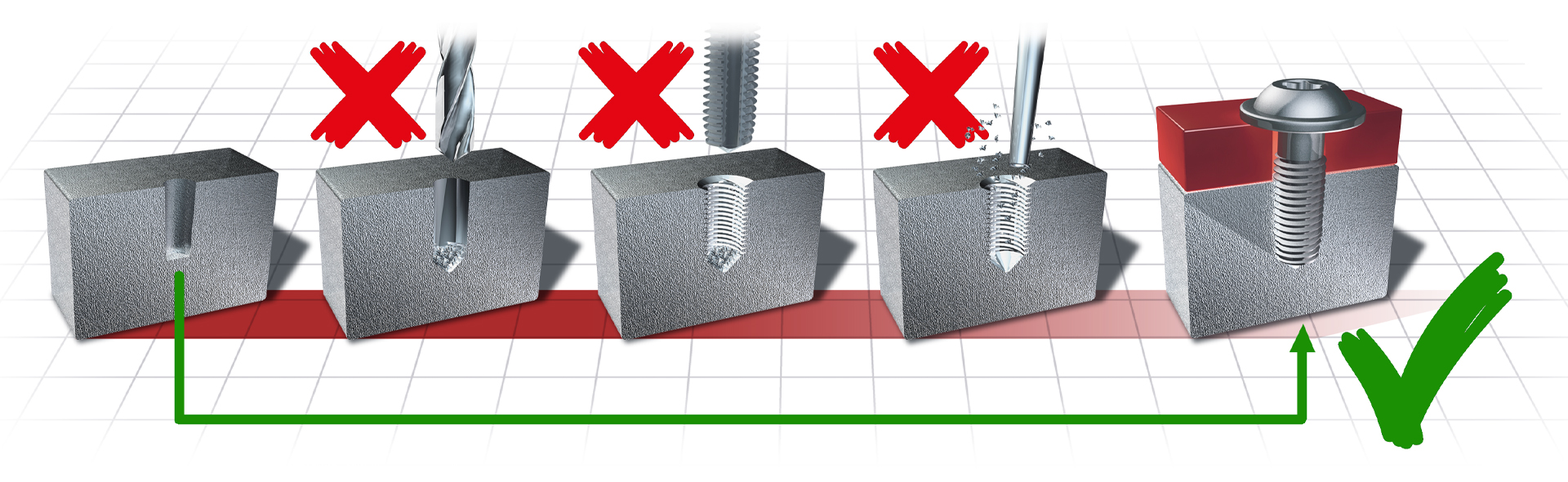

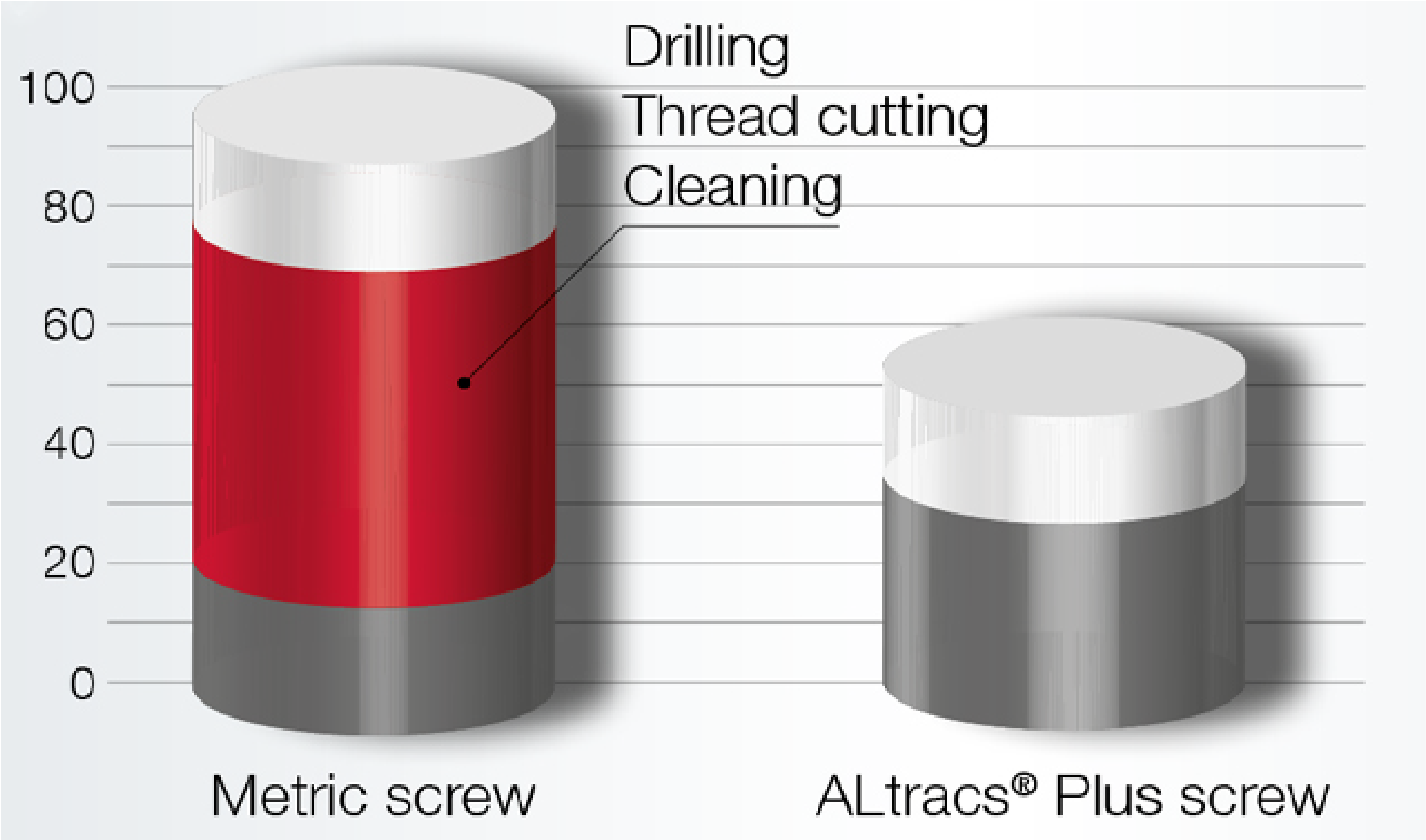

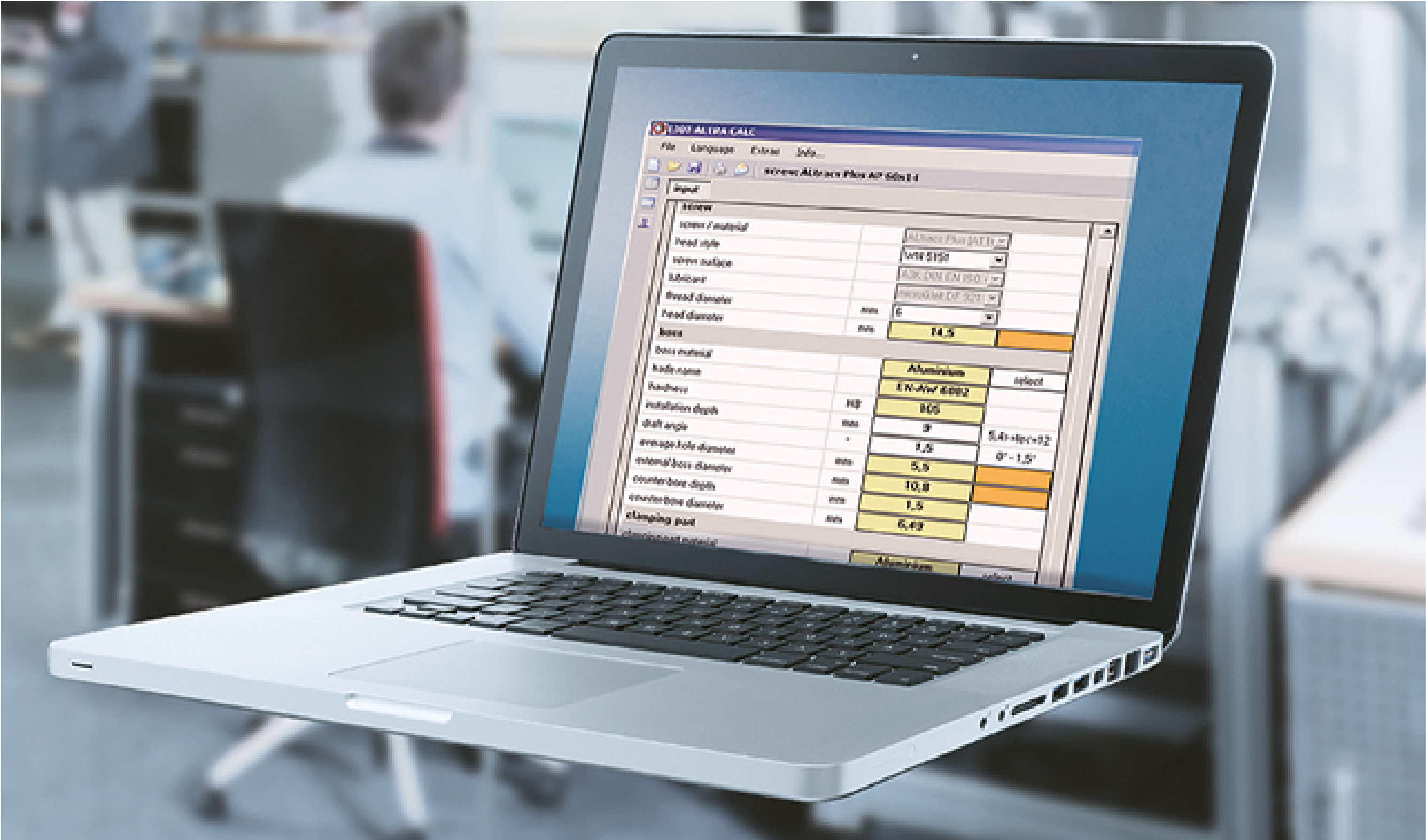

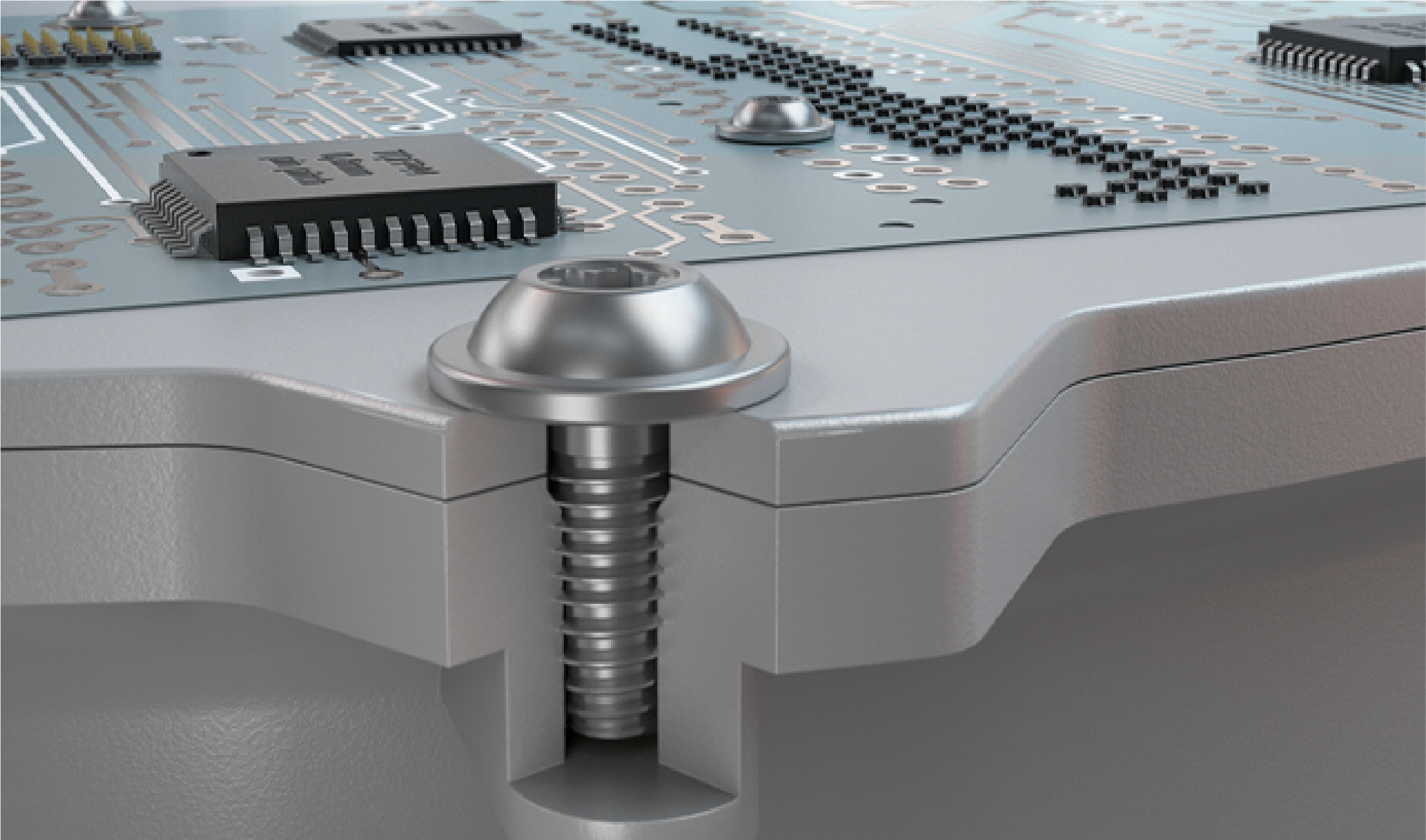

Designed specifically for direct thread-forming assembly into cast holes, EJOT ALtracs® Plus fasteners are developed to deliver maximum high-strength values in light alloy assemblies and other non-ferrous metals such as zinc, copper or brass. For designers, that means realtime cost savings can be gained easily when compared to metric screws, simply by removing processes such as drilling, thread cutting and cleaning.Innovative thread geometry

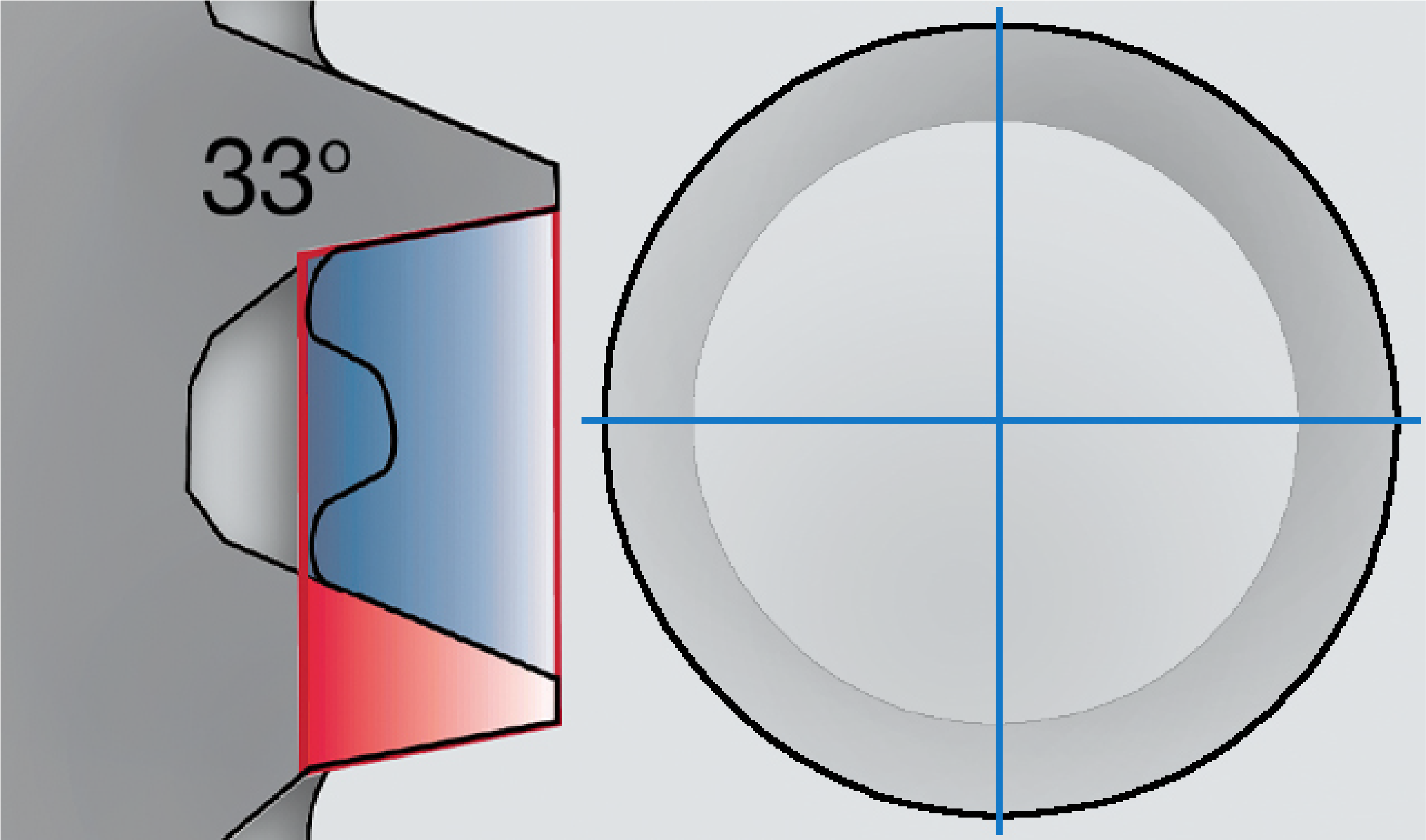

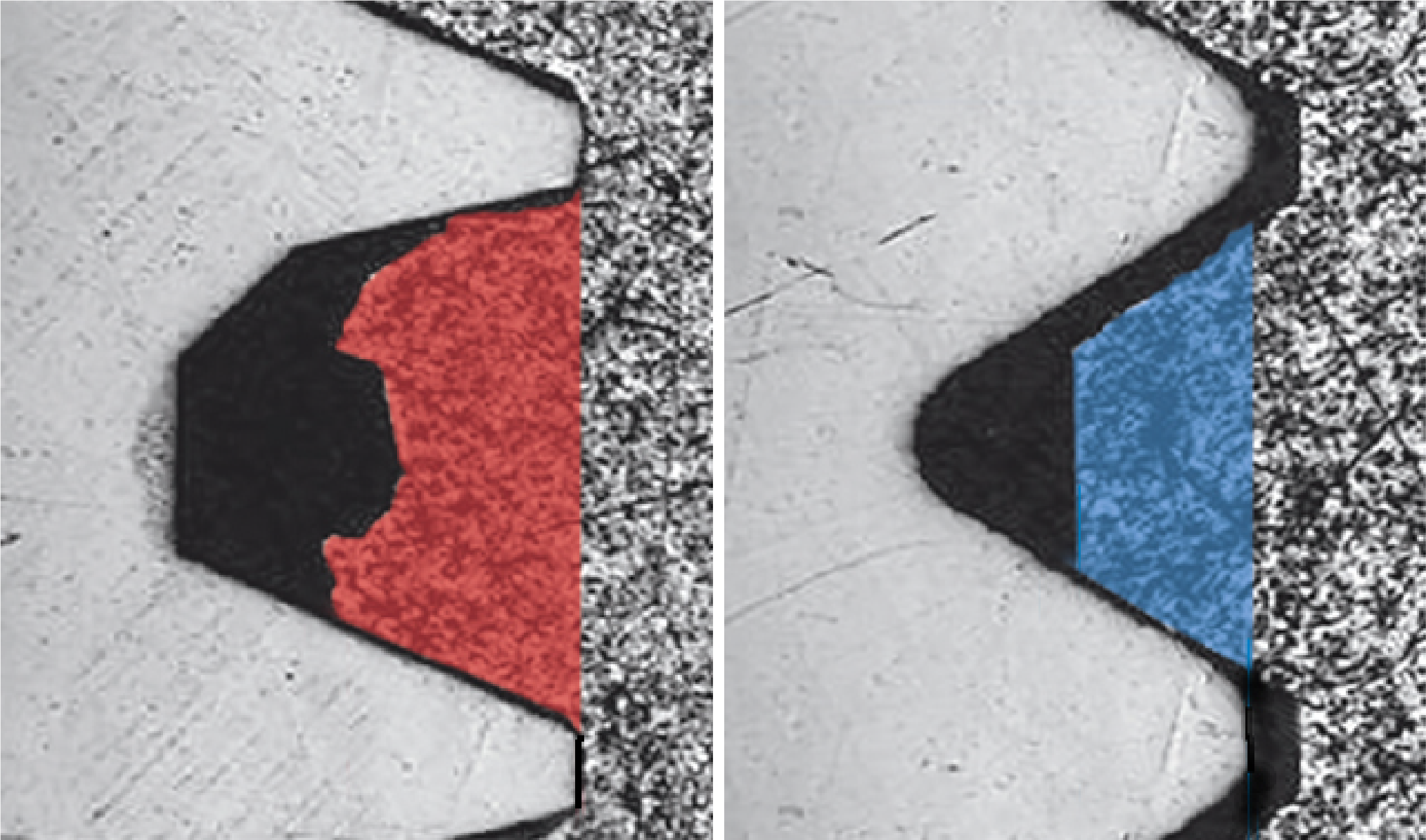

EJOT ALtracs® Plus fasteners have a unique optimised thread geometry and conical thread-forming zone that provides the option to use smaller, shorter screws, while retaining consistently high strength values and high vibration resistance - without the need to introduce additional safety elements into the joint.

Genuine cost and performance benefits

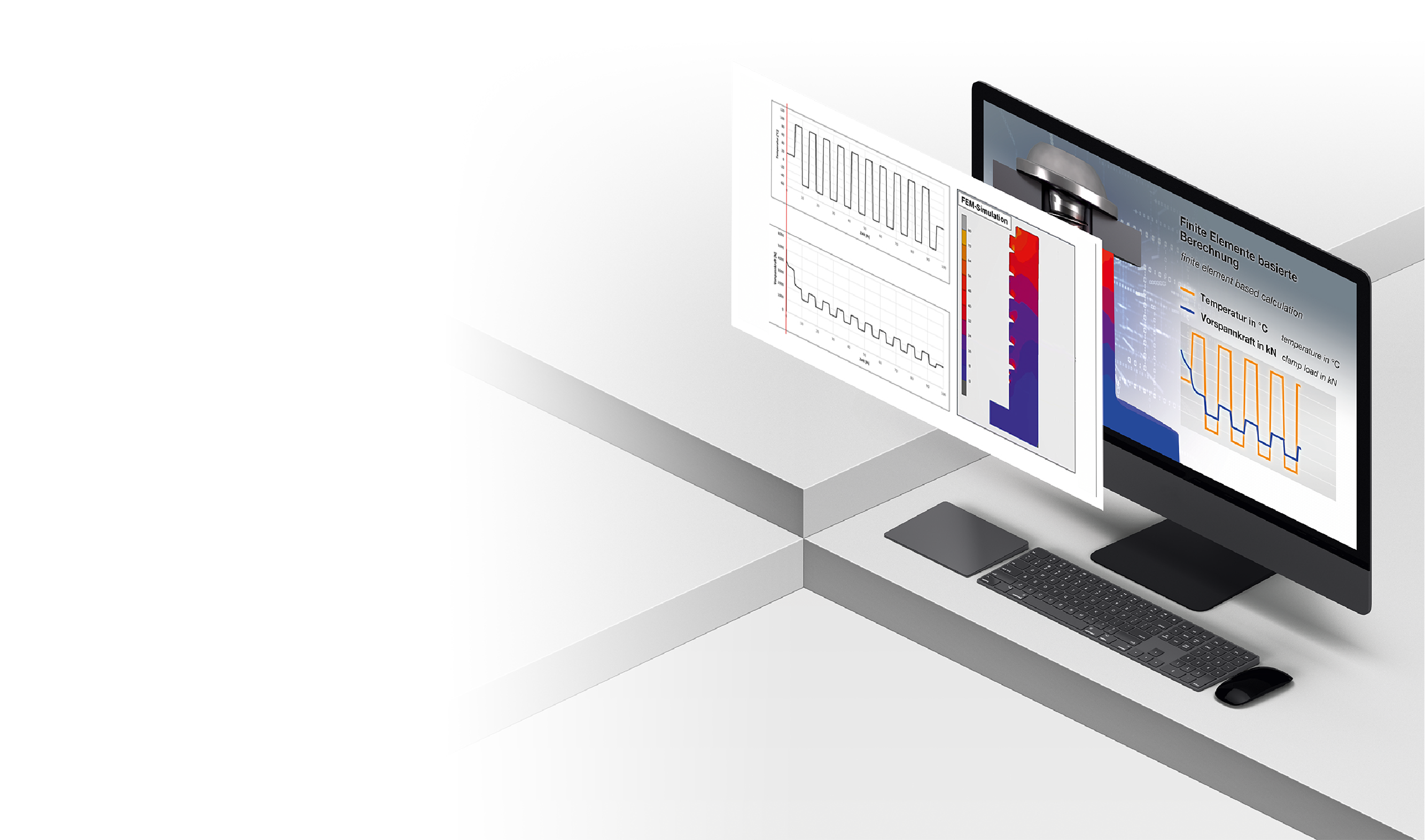

ALtracs® Plus is the second generation screw that builds on the original ALtracs® principle, offering improved technical capabilities! That means a high clamp load and relaxation process that creates long term strength - even under high dynamic and thermal stress - achieving strength values comparable to 10.9 metric screws.

Lower installation and higher stripping torque means that reliable assembly can easily be achieved with common pneumatic and electric screwdrivers. These features alone deliver performance advantages in addition to cost-savings of upto 40% when compared to metric screws!